IMS Messsysteme GmbH a world leader in X-ray, Gamma ray, coating measurement and optical thickness measurement systems: surface defects, width, flatness, pin holes and microholes; since 1980 it has been guaranteeing the highest quality products in the production and processing of steel, aluminum and nonferrous metals.

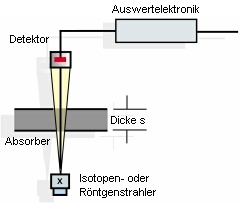

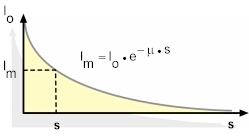

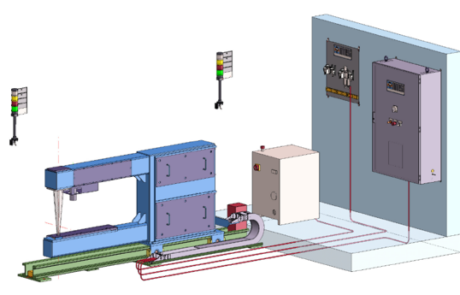

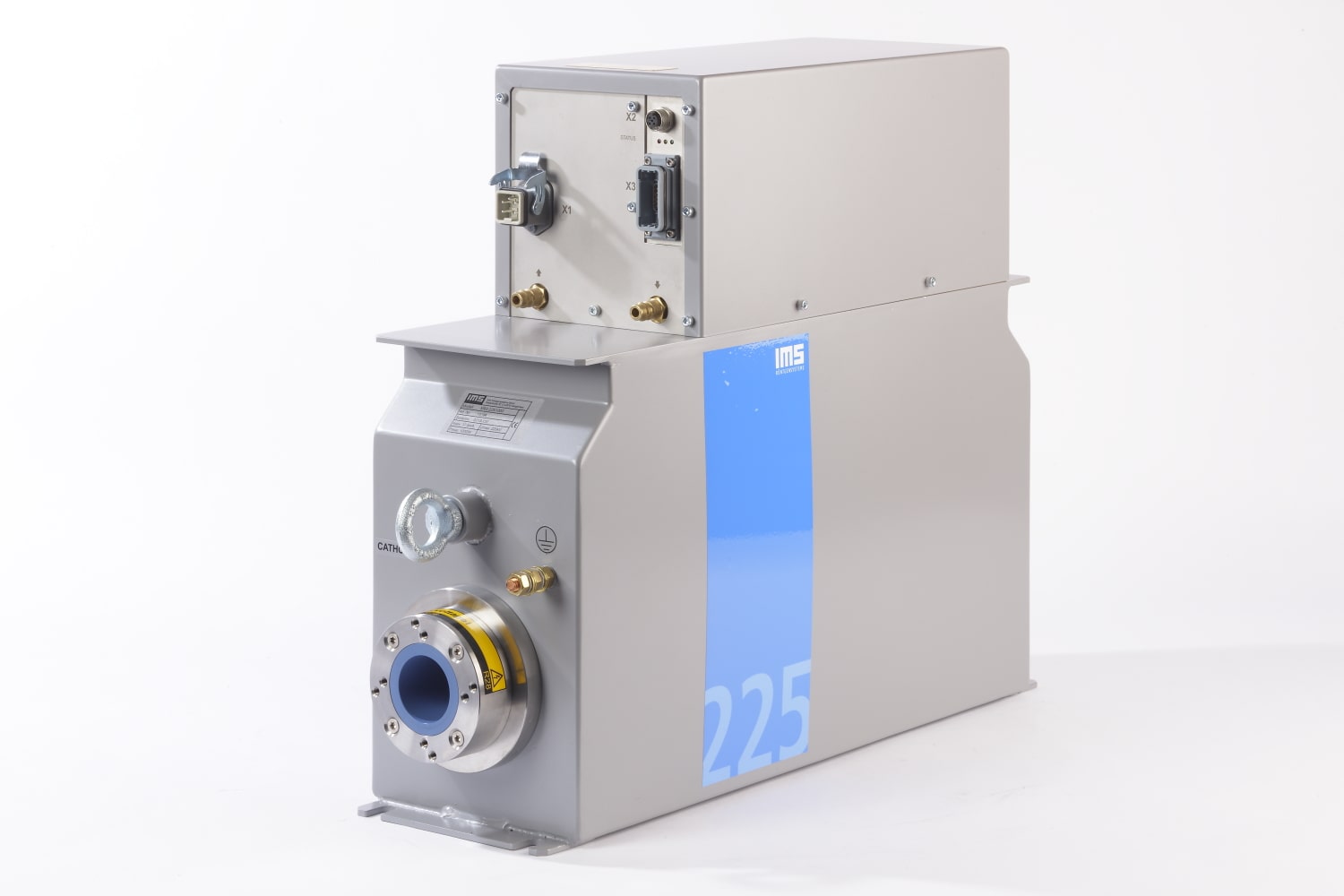

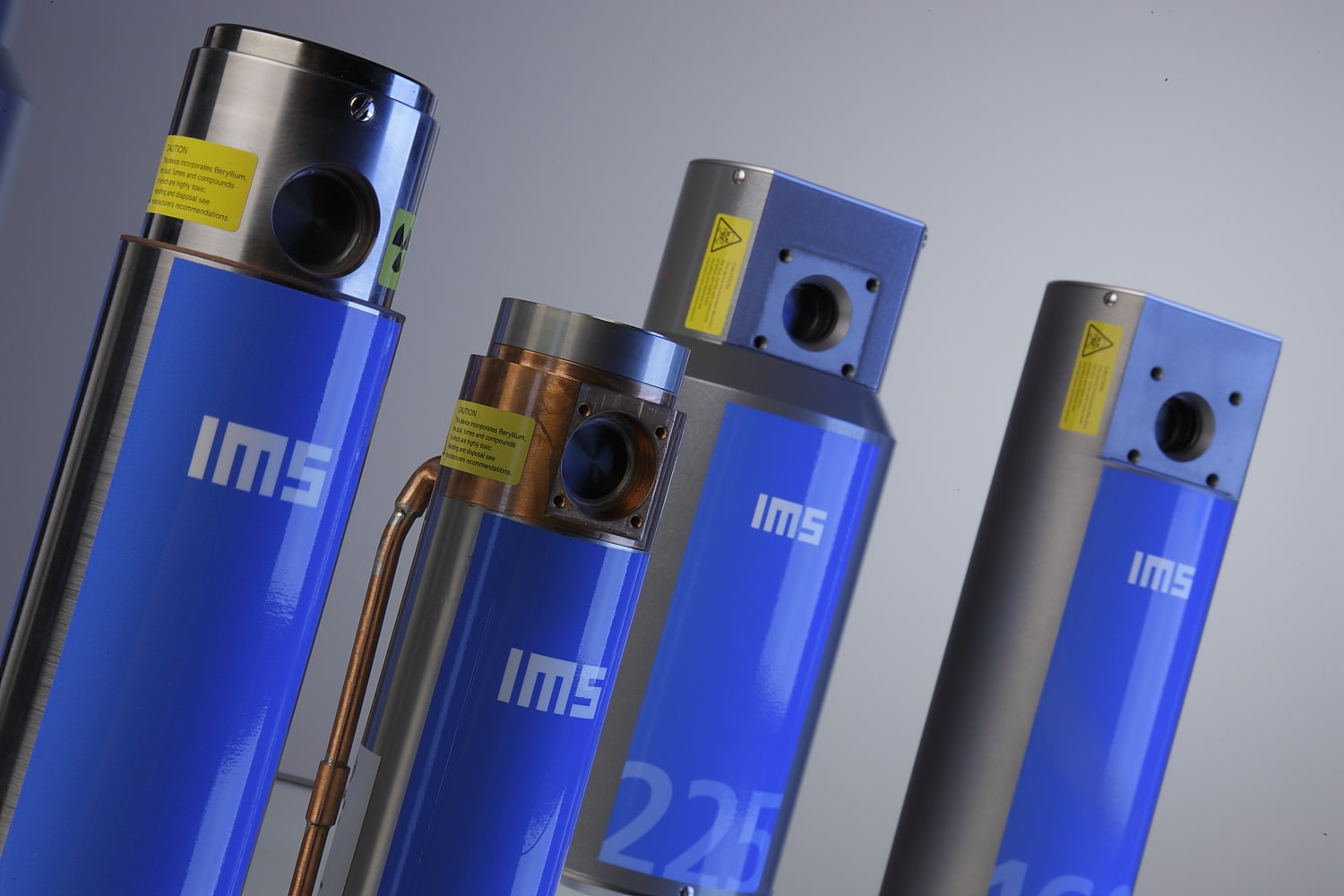

Non-contact thickness measurement IMS

IMS’s non-contact thickness measuring systems are the only ones in the world to use a single linearization curve over the entire thickness range of the rolling mill, this allows the life of the components (X-ray tubes and HV generators)to be extended, which have an average lifetime of more than 10 years.

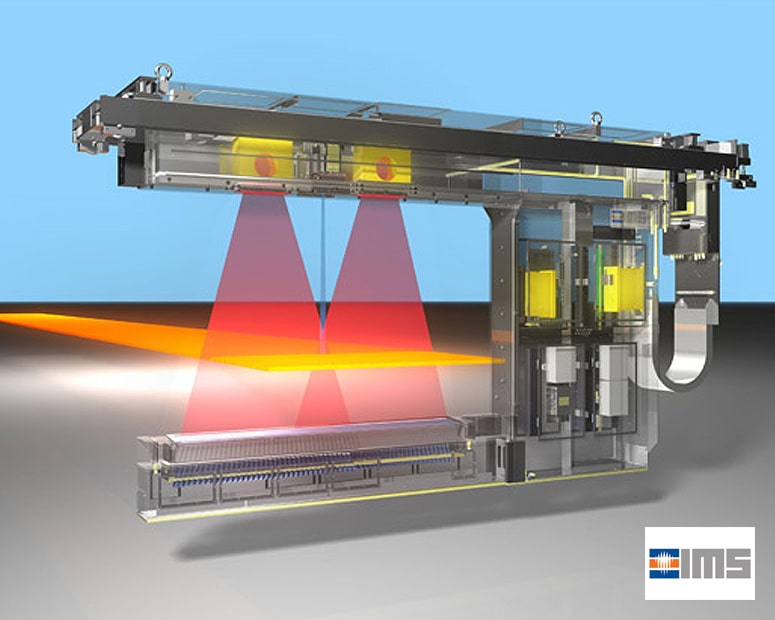

Surcon: surface inspection system (SIS)

IMS since 2008, began producing the Surcon, a surface defect measurement system. In 2010, the first instrument capable of measuring slab defects using 3-D technology was installed.

Today Ims is able to measure defects on: slabs, plates, hot and cold coils, pipes, long products.

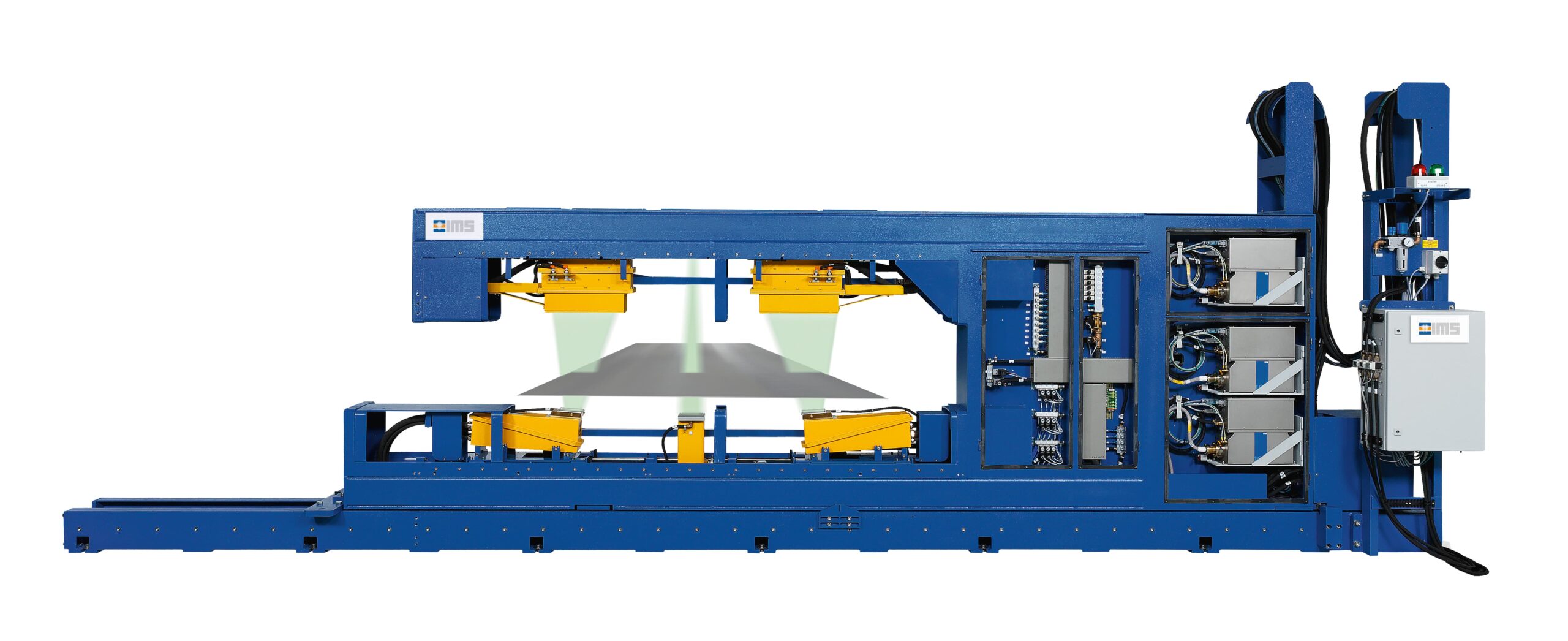

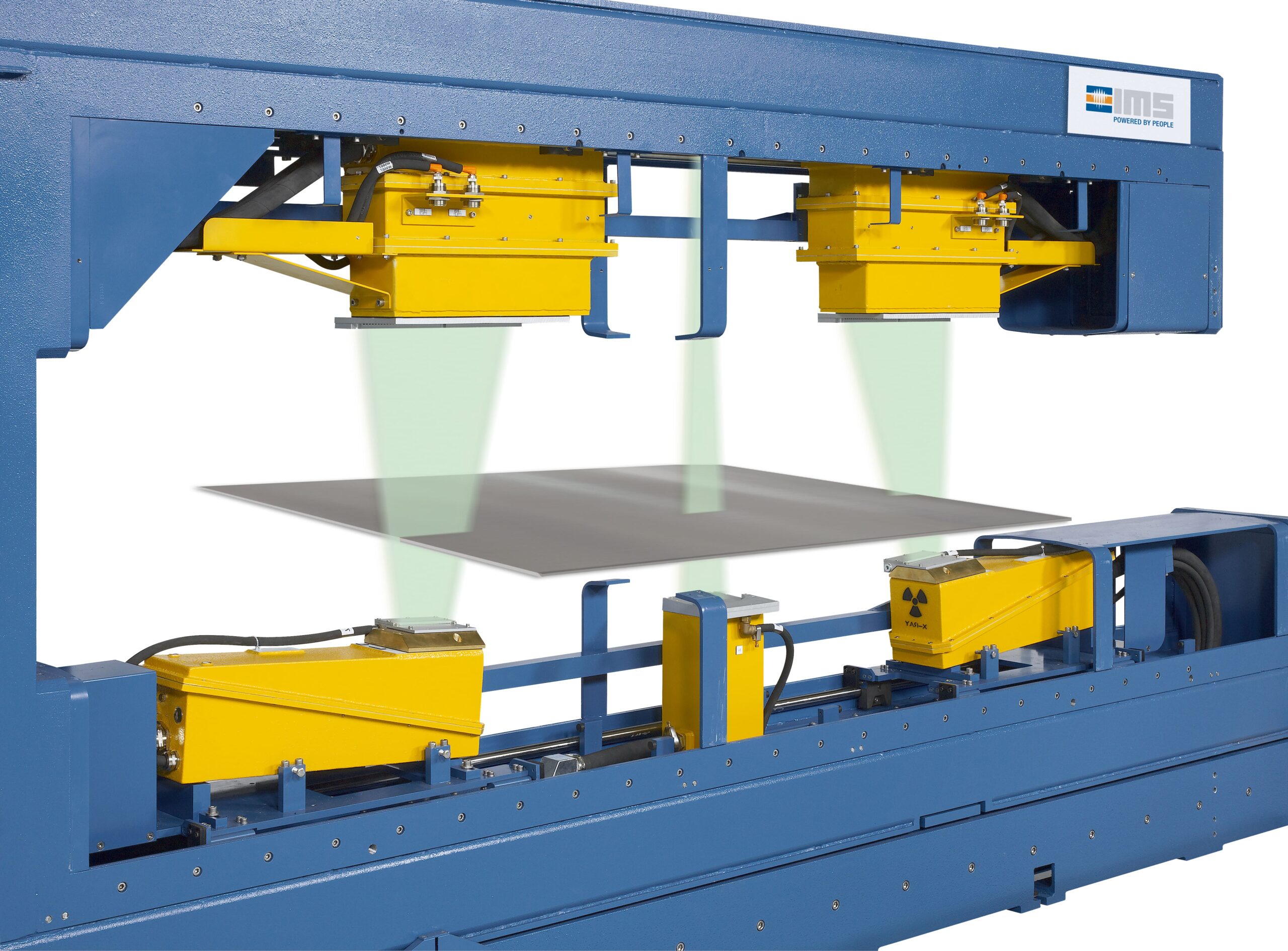

Worldwide Unique Camera Cluster Technology

IMS’ camera cluster systems (CCS) are based on fast and intelligent high-tech cameras. Due to their modular design, CCS systems can be easily adapted to any strip or sheet width.

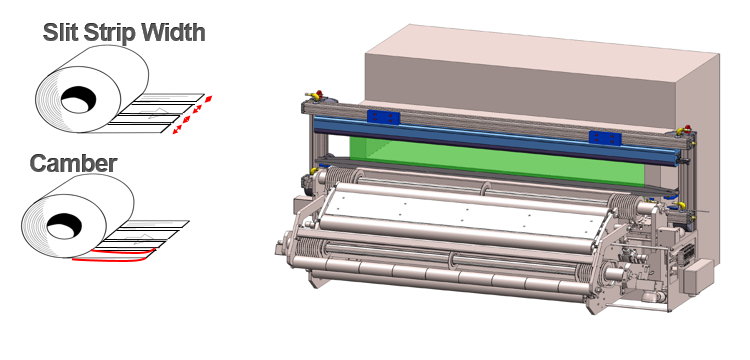

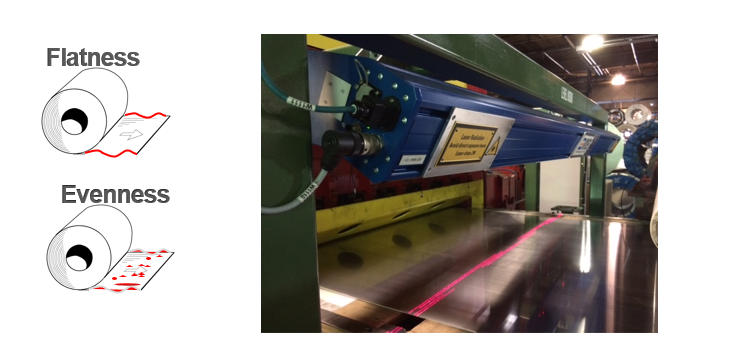

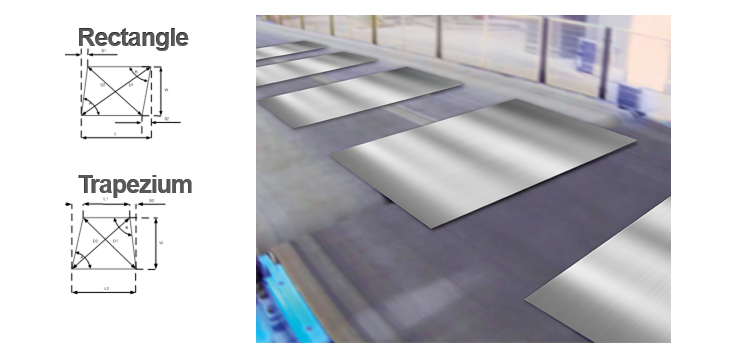

Using this technology Ims can make: width gauges, flatness, pinhole, geometric shape measurement systems, cut strip width, strip edge breakage verification.